The Ultimate Guide To 5S For Enhanced Workplace Efficiency

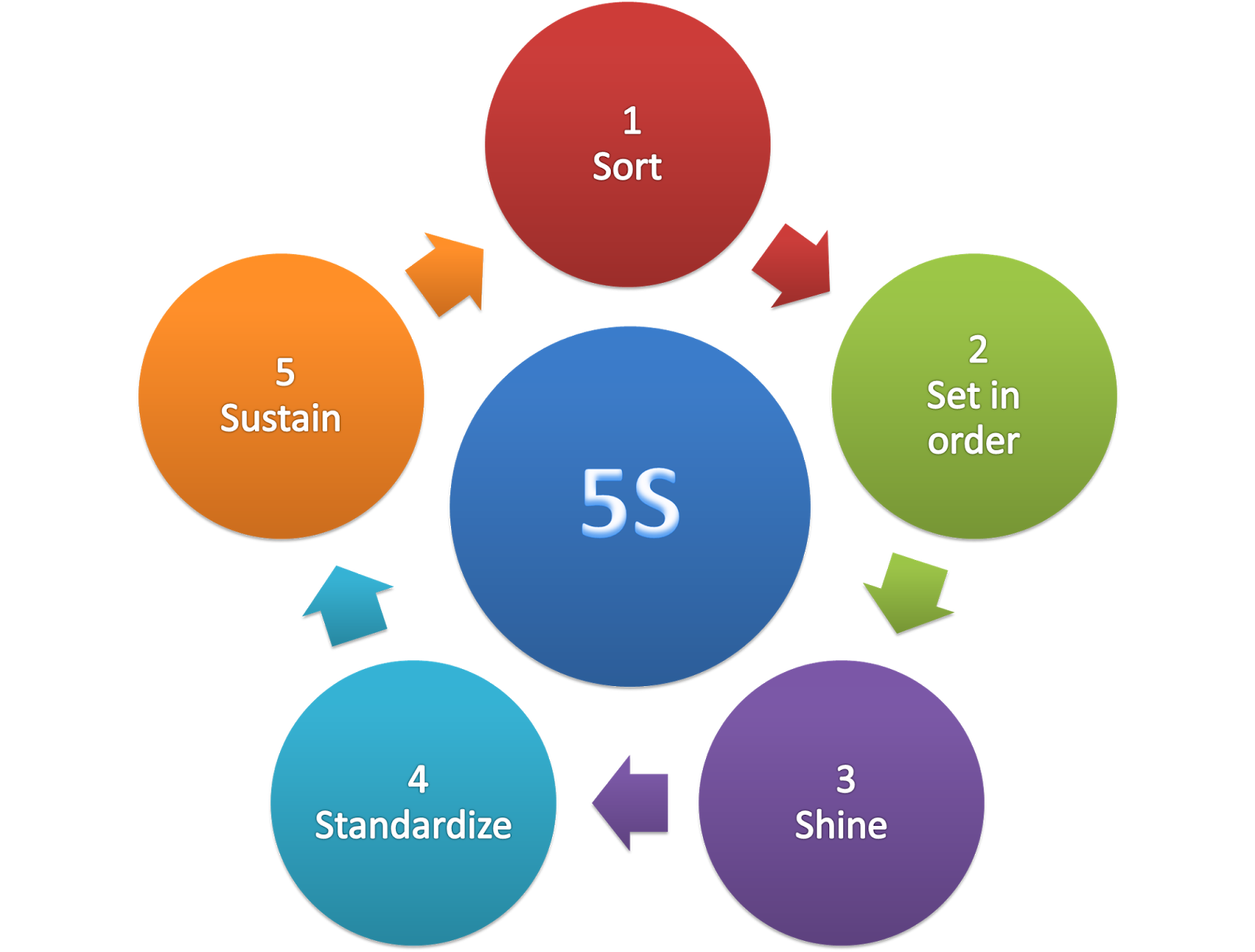

What is 5S? 5S is a workplace organization method that uses a list of five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke. These words translate to sort, straighten, shine, standardize, and sustain, respectively.

5S helps to create a more organized, efficient, and safe workplace by eliminating waste and improving productivity. It can be applied to any type of workplace, from offices to factories to hospitals.

The benefits of 5S are numerous. It can help to reduce waste, improve productivity, improve safety, and boost morale. 5S can also help to create a more positive and motivating work environment.

- Marvels Wade Wilson Unmasking The Killer Behind Deadpool

- The Ultimate Guide To Cecchis Nyc Experience Extraordinary Italian Cuisine

5S is a simple and effective way to improve the organization and efficiency of any workplace. It is a valuable tool that can help businesses to achieve their goals.

5S

5S is a workplace organization method that can help to improve efficiency, productivity, and safety. It is based on five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke, which translate to sort, straighten, shine, standardize, and sustain.

- Sort: Identify and remove unnecessary items from the workplace.

- Straighten: Organize items in a logical and efficient way.

- Shine: Clean and inspect the workplace regularly.

- Standardize: Create and follow standard procedures for all tasks.

- Sustain: Maintain the 5S system over time.

- Safety: 5S can help to improve safety by eliminating hazards and creating a more organized workplace.

5S can be applied to any type of workplace, from offices to factories to hospitals. It is a simple and effective way to improve the organization and efficiency of any workplace. By following the five steps of 5S, businesses can create a more productive, efficient, and safe workplace.

- Tragic Loss The Fatal End Of Brandon Lees Life

- Is Justin Timberlake Currently Incarcerated The Truth Revealed

Sort

Sorting is the first step in the 5S process, and it is essential for creating a more organized and efficient workplace. When unnecessary items are removed from the workplace, it becomes easier to find the items that are needed, and it also reduces the risk of accidents and injuries.

There are many different ways to sort items in the workplace. One common method is to use the "red tag" system. With this system, items that are no longer needed are tagged with a red tag. These items are then removed from the workplace and either discarded or stored in a designated area.

Another way to sort items in the workplace is to use the "5S shadow board" system. With this system, each item has a designated place on a shadow board. This makes it easy to see which items are missing and which items are out of place.

Sorting is an important part of the 5S process, and it can help to improve the organization and efficiency of any workplace.Straighten

Straightening is the second step in the 5S process, and it is essential for creating a more organized and efficient workplace. When items are straightened, they are arranged in a logical and efficient way, which makes it easier to find and use them.

There are many different ways to straighten items in the workplace. One common method is to use the "5S shadow board" system. With this system, each item has a designated place on a shadow board. This makes it easy to see which items are missing and which items are out of place.

Another way to straighten items in the workplace is to use the "first in, first out" (FIFO) method. With this method, items are used in the order in which they are received. This helps to prevent items from becoming outdated or damaged.

Straightening is an important part of the 5S process, and it can help to improve the organization and efficiency of any workplace. By straightening items in a logical and efficient way, businesses can save time and money, and they can also improve safety.

Shine

In the context of 5S, "Shine" refers to the regular cleaning and inspection of the workplace. This is an important step in maintaining a clean, organized, and safe work environment.

- Improved productivity

A clean and organized workplace can help to improve productivity by reducing the time it takes to find tools and materials. It can also help to reduce the risk of accidents and injuries.

- Enhanced safety

Regular cleaning and inspection can help to identify and eliminate potential hazards, such as spills, leaks, and damaged equipment. This can help to prevent accidents and injuries.

- Improved morale

A clean and organized workplace can help to improve morale by creating a more positive and inviting work environment. This can lead to increased employee satisfaction and productivity.

- Reduced waste

Regular cleaning and inspection can help to identify and eliminate waste, such as unnecessary items and materials. This can help to save money and improve efficiency.

Shining is an important part of 5S, and it can help to improve the safety, productivity, and efficiency of any workplace.

Standardize

Standardization is the fourth step in the 5S process, and it is essential for creating a more efficient and effective workplace. When standard procedures are created and followed, it becomes easier to train new employees, improve quality, and reduce waste.

- Improved efficiency

Standard procedures can help to improve efficiency by reducing the time it takes to complete tasks. When everyone knows how to do a task the same way, there is less confusion and rework.

- Enhanced quality

Standard procedures can help to enhance quality by ensuring that tasks are completed consistently and correctly. This can lead to fewer errors and defects.

- Reduced waste

Standard procedures can help to reduce waste by eliminating unnecessary steps and duplication. This can save time and money.

- Improved safety

Standard procedures can help to improve safety by ensuring that tasks are completed safely. This can help to prevent accidents and injuries.

Standardization is an important part of 5S, and it can help to improve the efficiency, quality, and safety of any workplace.

Sustain

Sustaining the 5S system is essential for maintaining a clean, organized, and efficient workplace. It involves creating a culture of continuous improvement and ensuring that everyone in the workplace is committed to following the 5S principles.

- Regular audits

Regular audits are essential for ensuring that the 5S system is being followed. Audits should be conducted by a team of employees from different departments, and they should focus on all aspects of the 5S system, from sorting and straightening to shining and standardizing.

- Employee training

Employee training is another important aspect of sustaining the 5S system. Employees need to be trained on the 5S principles and how to apply them in their own work areas. Training should be conducted regularly, and it should be tailored to the specific needs of the workplace.

- Management support

Management support is essential for sustaining the 5S system. Managers need to be committed to the 5S principles, and they need to provide the resources and support that employees need to implement and maintain the system.

- Continuous improvement

The 5S system is not a static system. It should be continually improved to meet the changing needs of the workplace. Employees should be encouraged to suggest improvements to the system, and management should be open to new ideas.

Sustaining the 5S system is an ongoing process, but it is essential for maintaining a clean, organized, and efficient workplace. By following the tips above, businesses can create a workplace that is more productive, safe, and enjoyable for everyone.

Safety

5S is a workplace organization method that can help to improve safety by eliminating hazards and creating a more organized workplace. By following the five steps of 5S, businesses can create a safer work environment for their employees.

- Hazard elimination

5S can help to eliminate hazards by identifying and removing potential hazards from the workplace. For example, by sorting and straightening items, businesses can eliminate trip and fall hazards. By shining the workplace, businesses can identify and potential fire hazards.

- Improved organization

5S can help to improve organization by creating a more organized and efficient workplace. This can help to reduce the risk of accidents and injuries. For example, by standardizing procedures, businesses can reduce the risk of errors that could lead to accidents.

- Increased awareness

5S can help to increase awareness of safety hazards by creating a more visible and organized workplace. This can help employees to identify and avoid potential hazards.

- Improved morale

5S can help to improve employee morale by creating a safer and more organized workplace. This can lead to increased productivity and reduced absenteeism.

5S is a simple and effective way to improve safety in the workplace. By following the five steps of 5S, businesses can create a safer and more organized workplace for their employees.

5S FAQs

The following are some frequently asked questions about 5S:

Question 1: What is 5S?

Answer: 5S is a workplace organization method that uses a list of five Japanese words: seiri, seiton, seiso, seiketsu, and shitsuke. These words translate to sort, straighten, shine, standardize, and sustain, respectively.

Question 2: What are the benefits of 5S?

Answer: 5S can help to improve efficiency, productivity, safety, and morale. It can also help to reduce waste and create a more positive work environment.

Question 3: How can I implement 5S in my workplace?

Answer: There are many different ways to implement 5S in the workplace. One common approach is to start by sorting and discarding unnecessary items. Once the workplace is sorted, it can be straightened and cleaned. Standard procedures can then be created and implemented for all tasks. Finally, it is important to sustain the 5S system over time.

Question 4: Is 5S only for manufacturing environments?

Answer: No, 5S can be applied to any type of workplace, from offices to hospitals to retail stores.

Question 5: How long does it take to implement 5S?

Answer: The time it takes to implement 5S will vary depending on the size and complexity of the workplace. However, most businesses can expect to see significant results within a few months.

Question 6: What are some common challenges to implementing 5S?

Answer: Some common challenges to implementing 5S include resistance from employees, lack of management support, and difficulty sustaining the system over time. However, these challenges can be overcome with proper planning and commitment.

Summary: 5S is a simple and effective way to improve the organization and efficiency of any workplace. By following the five steps of 5S, businesses can create a more productive, safe, and enjoyable work environment for everyone.

Transition: To learn more about 5S, please read the following article:

Conclusion

5S is a powerful tool that can help businesses to improve efficiency, productivity, safety, and morale. By following the five steps of 5S, businesses can create a more organized and efficient workplace that is safer and more enjoyable for everyone.

5S is not a one-time event. It is an ongoing process that requires commitment from everyone in the workplace. By sustaining the 5S system over time, businesses can reap the benefits of a more organized and efficient workplace for years to come.

Detail Author:

- Name : Otis Cronin

- Username : bosco.amiya

- Email : rae.cruickshank@yahoo.com

- Birthdate : 1989-04-29

- Address : 970 Johns Dam Port Daynaborough, MA 33674-0986

- Phone : +1.786.870.3593

- Company : Jaskolski PLC

- Job : Desktop Publisher

- Bio : Fugit et aliquid veritatis quisquam veritatis hic omnis. Reiciendis suscipit voluptatem illum et soluta dolorem sed. Voluptatum libero error ipsum temporibus impedit et.

Socials

linkedin:

- url : https://linkedin.com/in/davontemcdermott

- username : davontemcdermott

- bio : Modi quis unde non aut.

- followers : 3327

- following : 1594

twitter:

- url : https://twitter.com/mcdermottd

- username : mcdermottd

- bio : Sit rerum ea harum. Voluptatem deleniti rem debitis iste labore deserunt neque. Autem dolorem culpa et perspiciatis. Qui voluptatem accusamus rem ducimus.

- followers : 4731

- following : 1185